The first choice for professionals down to the last detail.

The advantages of BG-FILCOTEN® pro mini.

The first choice for professionals down to the last detail.

The advantages of BG-FILCOTEN® pro mini.

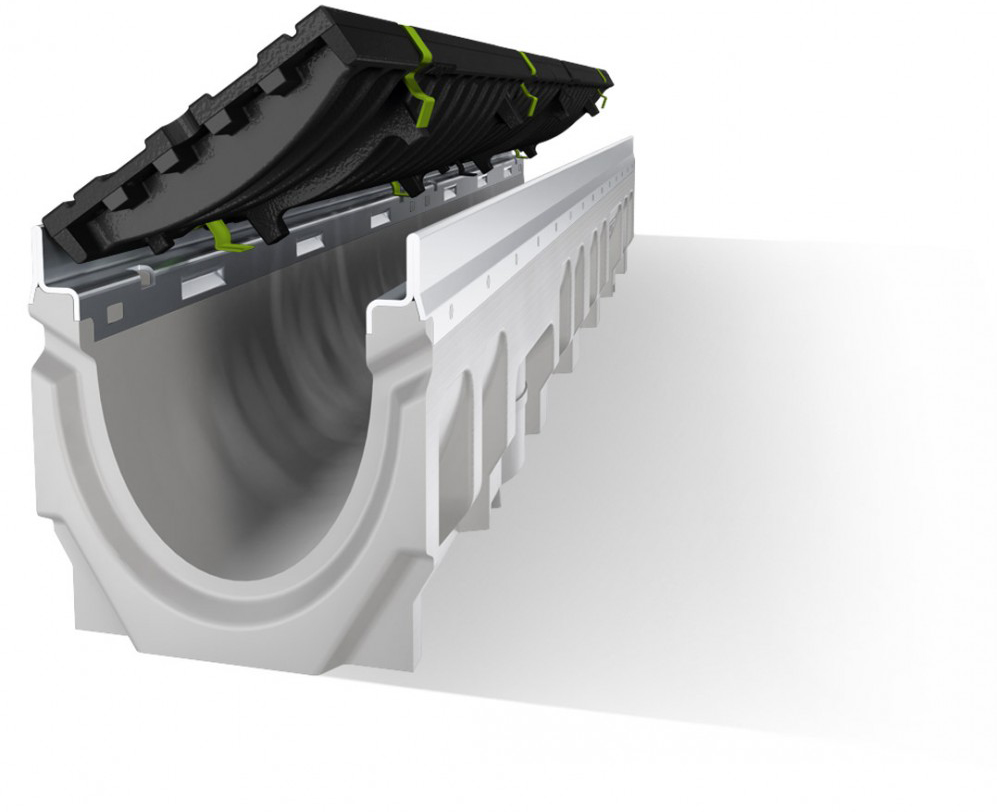

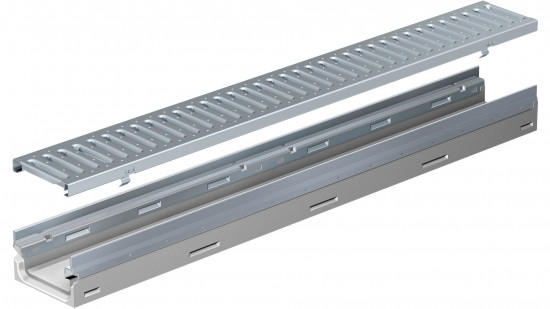

<p>Click on the green symbols in the image to find out more about the design of the BG-FILCOTEN® pro mini drainage channel.</p>

+

+

+

+

+

+

+

+

FILCOTEN® HPC:

Like traditional concrete,

only better.

FILCOTEN® HPC:

Like traditional concrete,

only better.

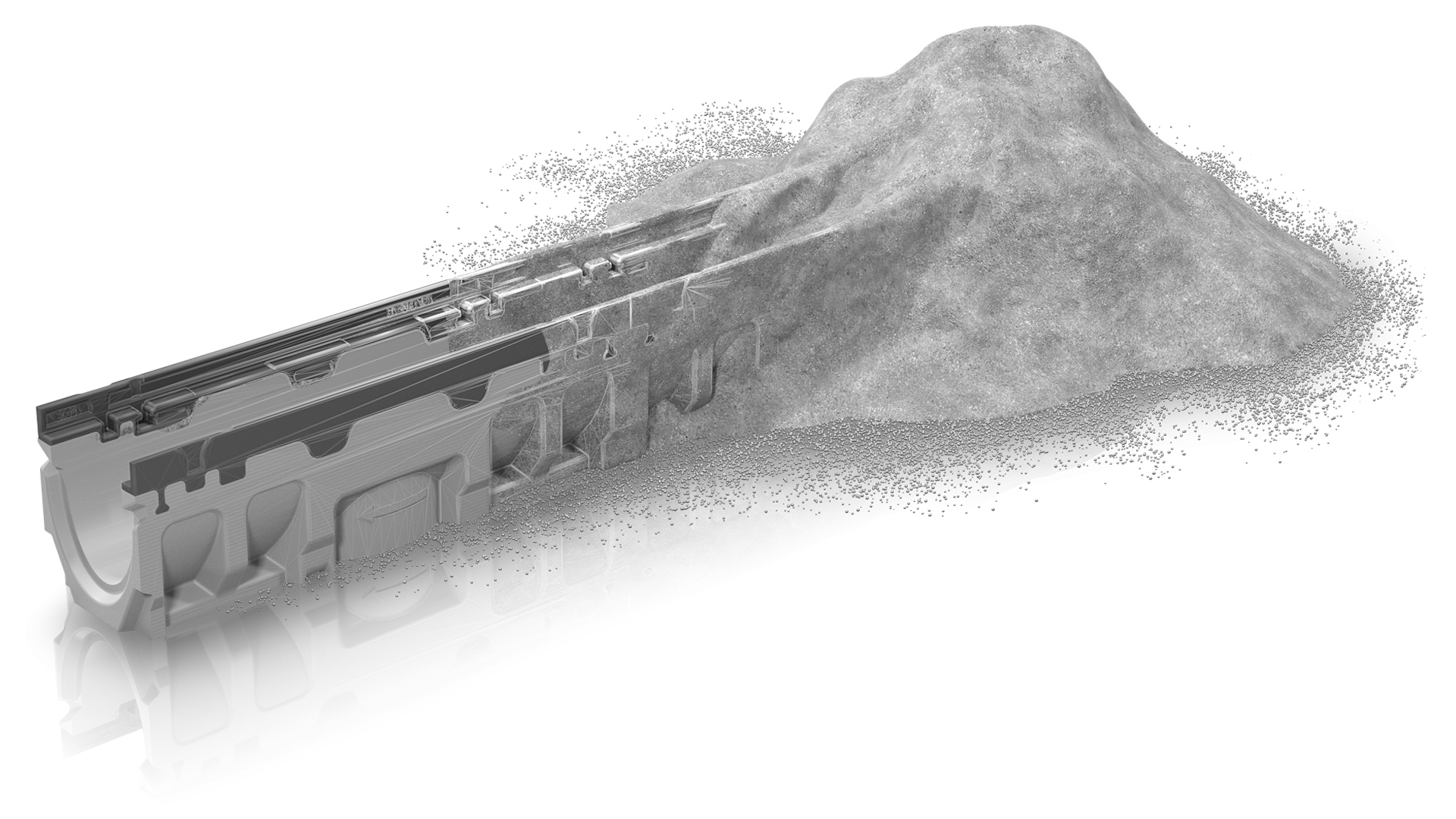

<p>FILCOTEN® HPC high-performance, 100% mineral concrete is an enhanced form of conventional concrete. Its engineering and ecological properties are achieved without the use of any styrenes, synthetic fibres or polymers. The optimised high-density structure of HPC makes it possible to construct highly stable, lightweight drainage channels – but it’s the idea behind it that makes it unique. </p>

Material and product benefits FILCOTEN® HPC

Material and product benefits FILCOTEN® HPC

Minimal weight

- FILCOTEN® HPC enables lightweight construction

- Quick and easy to install

- Dimensionally stable, robust concrete elements

perfect hold in the concrete bed

- ideal coefficient of expansion, identical to that of the surrounding concrete

High drainage performance

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

Resistant to extreme temperatures and UV light

- Maximum resistance to frost and de-icing salt

- UV resistant

Fireproof

- Non-combustible construction material – Class A1

- so no harmful smoke development

Maximum durability

- Unsurpassed stability and durability

- Compressive strength far exceeding the requirements of EN 1433

Sustainability advantage

Sustainability advantage

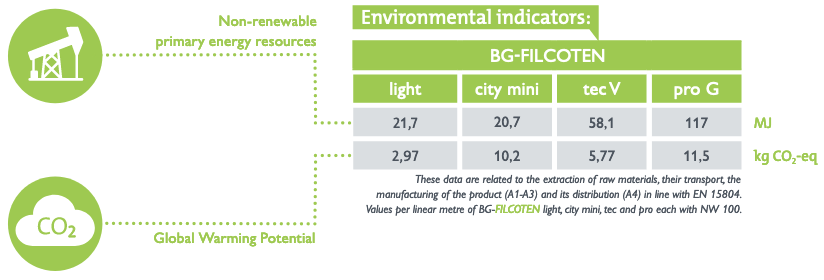

Verified life cycle assessment (LCA)

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

resource efficiency

- 100% recyclable, certified

- quality class U-A

Sustainable production

- resource-efficient manufacturing process

- up to 70 % less sand and gravel

- up to 55% less cement

- up to 51% less water

Clean energy for clean products

- manufactured using 100% green energy

- 17.56% from in-house photovoltaic plant

- No fossil fuels used whatsoever

Certified for sustainability and tested for hazardous substances

- Certified environmental and energy management to ISO 14001 or 50001 standards at the location in Oberwang/AT

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity; styrene-free

- Certified in acc. with KIWA BRL 5070

Any

questions?