Following countless hours of construction, design, planning and testing, we are presenting the first monolithic channel for dynamic loads made from FILCOTEN® HPC, a high-performance concrete.

The new number one

FILCOTEN® one

The new number one

FILCOTEN® one

<p><strong>A drainage channel – and a milestone</strong></p><p>channels have been around for about 20 years. While the idea of developing this kind of system from a mineral, cement-bound material isn’t new, it’s a great challenge, and no manufacturer has been able to meet it so far. We have put in a lot of work, broadening the limits of our mold construction and adding sophisticated features. <strong>Following intensive construction, design, planning and testing phases</strong>, we have finally reached our goal: adding a monolithic system to our products in the box drain and water management range.</p><p>Steffen Bernauer (Manager Product Development at BG) on the development process:</p>

BG-FILCOTEN® one was a challenge, in particular with regard to molding technology and the implementation in the production process. This is why we are even more satisfied with the positive feedback we are receiving throughout the market.

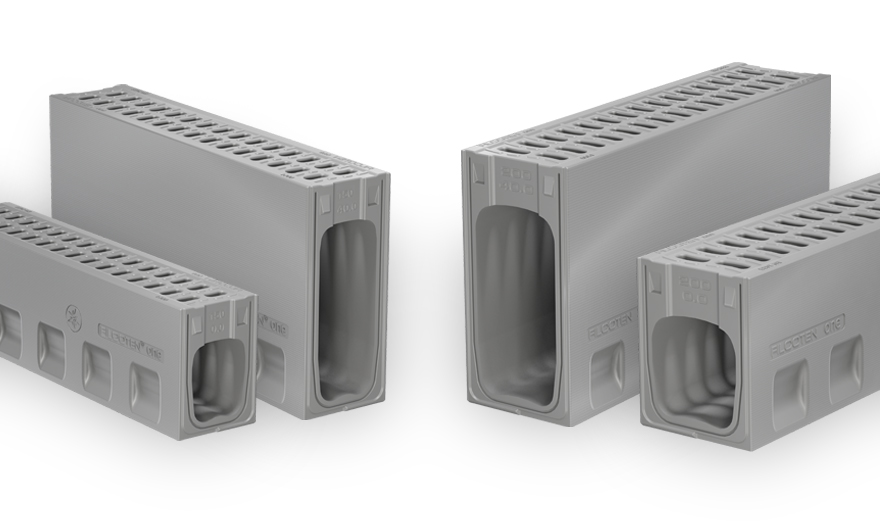

<p><strong>Why monolithic?</strong></p><p>BG-FILCOTEN® one is <strong>made from one piece, which makes it extremely robust, wear-resistant and highly sustainable.</strong> It is ideally suited for the dynamic loads occurring in parking and airport areas as well as on highways. Thanks to the monolithic structure, using a traditional casting grate is no longer necessary, as the entire channel system is made from highly-solid FILCOTEN® HPC. Another advantage of the monolithic structure: no loosening of components due to frequent traffic or heavy loads.</p><p> </p><h5><strong>Sustainable like no other</strong></h5><p>Karl-Heinz Gramlich (Director Product Management) on FILCOTEN® one:</p>

We want to be measured by our high ecological standards. Therefore, we have commissioned an independent body to perform an environmental lifecycle assessment of FILCOTEN® one in line with approved guidelines. This data is available to our customers on request.

<p>Throughout the assessment, all environmental indicators that we impacted ourselves were analyzed and verified. As an example, this includes primary energy consumption of non-renewable energies, assessed water requirements and greenhouse gas emissions as the most important indicators for the lifecycle phases of raw material procurement, production, internal logistics and transport to the construction site.</p><p> </p><p>The fact that we <strong>are committed to 100 % green energy and resource-saving use of material</strong> positively impacted the assessment, as did our FILCOTEN® HPC construction material. By publishing the results, we give our customers the opportunity to integrate our data into the <strong>environmental lifecycle assessment</strong> for their construction projects.</p><p> </p><p>FILCOTEN® HPC is purely mineral and styrene-free. The high-performance concrete is<strong> 100 % recyclable</strong> and has been tested for solvents, resins, biocides, VOCs as well as heavy metals, <strong>meeting</strong> the strict criteria of the Institute for Biologically Sound Construction Rosenheim (IBR).</p>

<p><strong>Naturally beautiful:</strong></p><p>Naturally beautifulThanks to its monolithic structure, FILCOTEN® one, made from FILCOTEN® HPC, is also a highlight when it comes to appearance. The high-quality channel body with its typical concrete color surface in an exposed concrete style blends in perfectly with the surroundings. </p>

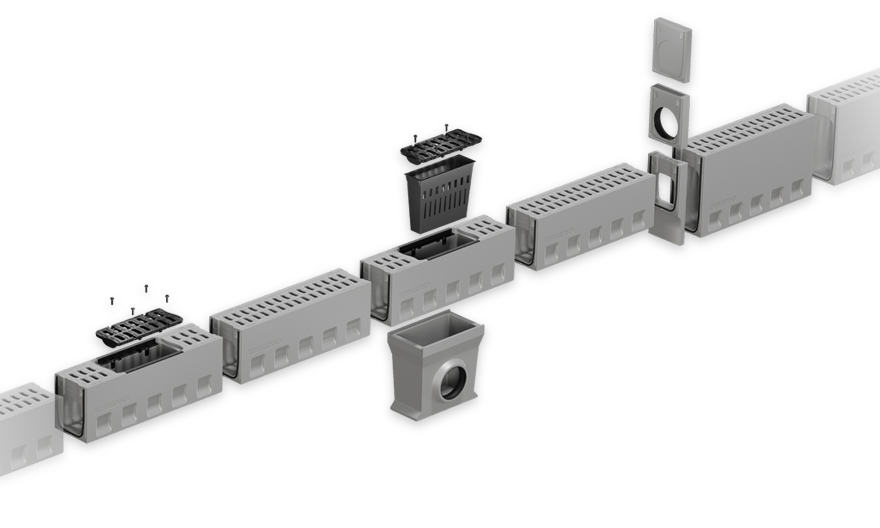

<p><strong>The system at a glance</strong></p><p>Since we added a whole range of intelligent solutions, BG-FILCOTEN® one is greater than the sum of its parts. These solutions ensure <strong>more efficiency, safety and performance </strong>when installed, used and maintained.</p>

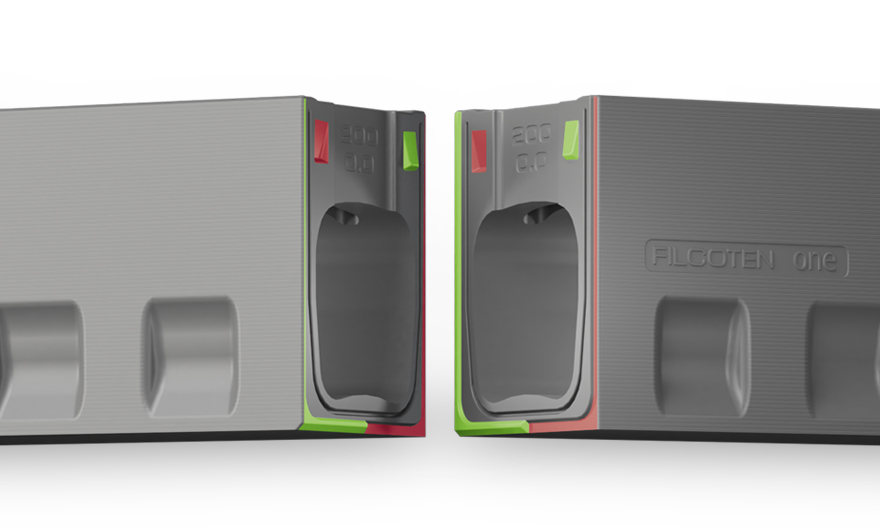

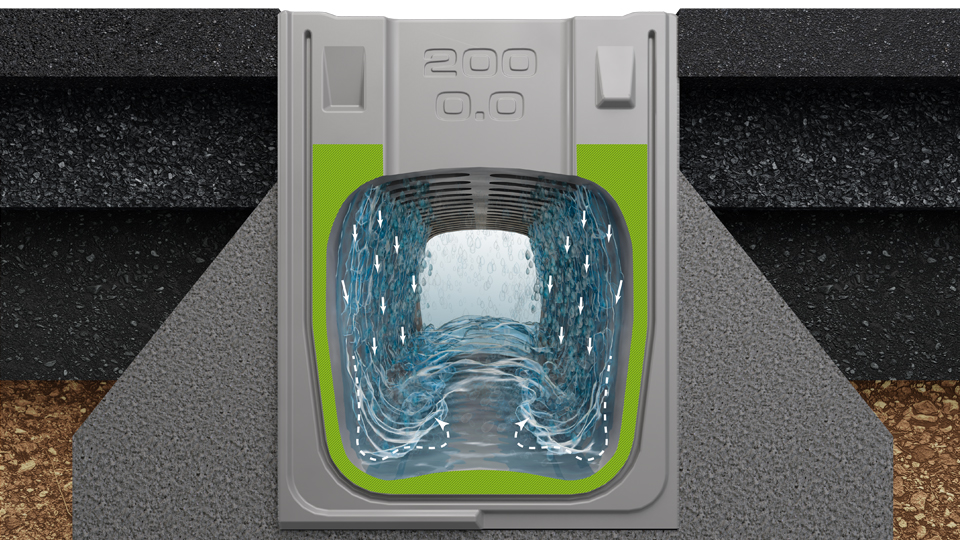

<p> </p><p>Optimized intake openings</p><p>The optimized intake openings for efficient rainwater intake are most visible for road users. They can be safely driven and walked across thanks to their counterrotating radial arrangement.</p><p><br>Tongue/Groove/tenon system for easy installation and fitting</p><p>The tongue/Groove/tenon system that can be installed in either direction enables easy and quick installation and precise, correctly aligned fitting of elements. Planning and installation of the system is simplified, as there are fewer individual parts. The adapter, front and end plates are also equipped with the groove/spring/pin system.</p><p> </p><p>Highly efficient water run</p><p>The channel cross-section in a wave profile design ensures maximum hydraulic capacity at partial and complete filling. Swirling of the inflowing water enables excellent self-cleaning properties.</p><p> </p><p>Intelligent sealing system</p><p>The optional seal is simply inserted into the circumferential groove on the channel body. Integrated lamellae on the sealing profile prevent it from slipping out. The Tongue/Groove/tenon system ensures optimal sealing.</p><p> </p><p>Revision element</p><p>The revision element in the style of a channel run comes with a removable class F900 grating for easy cleaning of the drainage unit.</p><p> </p>

<p>BG-FILCOTEN® one is available in the nominal widths 150 and 200 and construction heights no. 0 (335 mm (13.2″)) and 40-0 (535 mm (21.1″)). The latter offers a more powerful hydraulic performance and <strong>an additional retention volume of 40 l/m.</strong> Both construction heights can be combined without difficulty.</p><p> </p><p><strong>A BG-Graspointner quality channel</strong></p><p>We orient our everyday activities on our most important corporate values: sustainability and innovation.</p><p><br>Karl-Heinz Gramlich:</p>

BG-FILCOTEN® one is the latest result of our efforts to develop powerful products with innovative, sophisticated features, at the same time assuming responsibility for the future of our environment.

<p><strong>Take a look at the<strong><a href="http://www.graspointner.at/fileadmin/Prospekte/FCT_one_screen.pdf"> product brochuer</a></strong>to find out more about BG-FILCOTEN® one.</strong><br> </p>

<p>The most important features of FILCOTEN® one, explained in a 3D video</p>