Down to the last detail,

the top choice for professionals.

Down to the last detail,

the top choice for professionals.

+

+

+

+

+

+

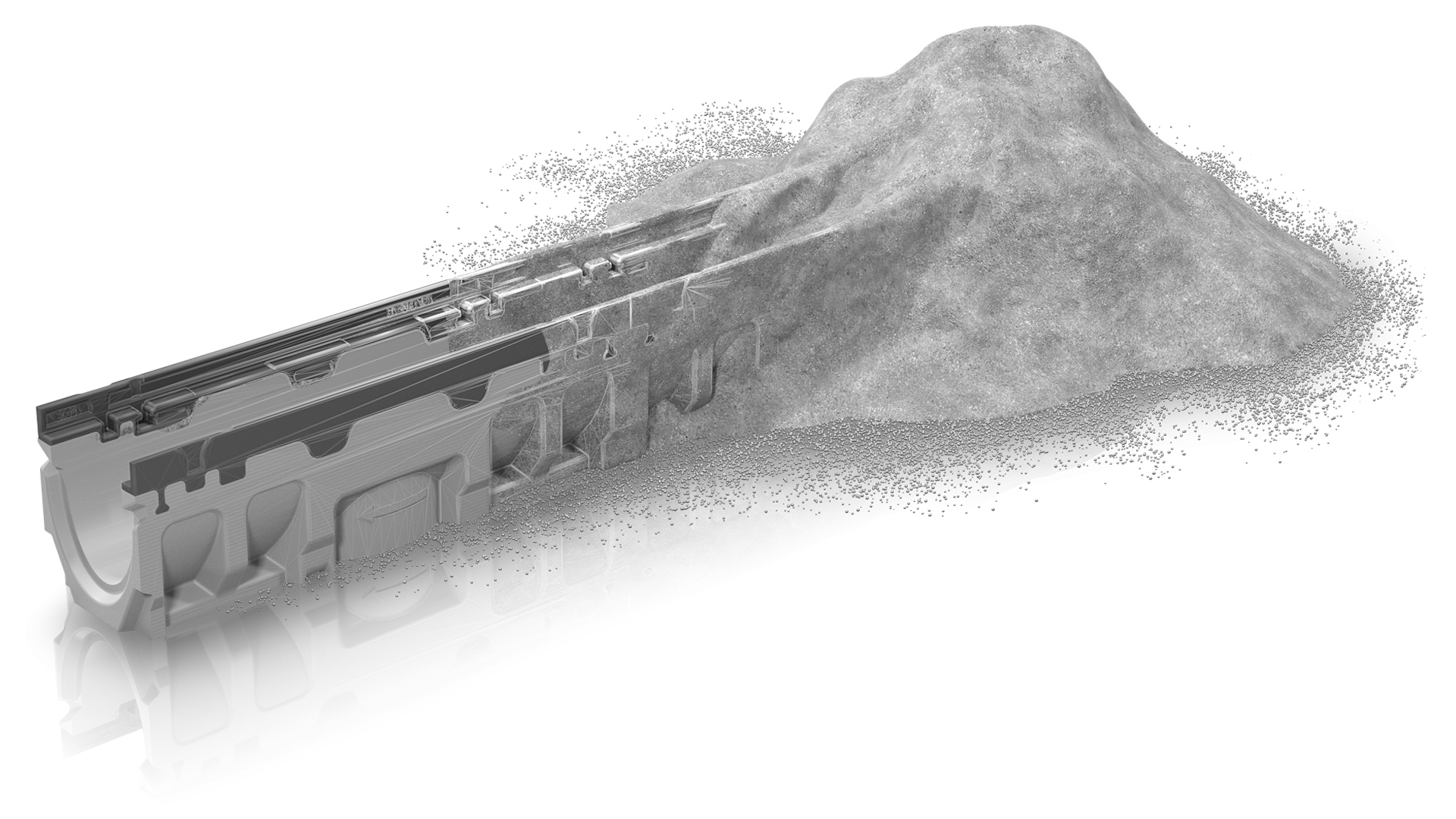

FILCOTEN® HPC:

Like standard concrete,

simply better.

FILCOTEN® HPC:

Like standard concrete,

simply better.

<p>FILCOTEN® HPC high-performance, 100% mineral concrete is an enhanced form of standard concrete. Its engineering and ecological properties are achieved without the use of any styrenes, synthetic fibers or polymers. HPC (High Performance Concrete) offers superior mechanical properties, enabling the manufacture of lighter concrete components. </p>

Material and product benefits of FILCOTEN® HPC

Material and product benefits of FILCOTEN® HPC

Minimal weight

- FILCOTEN® HPC enables lightweight construction

- Quick and easy to install

- Dimensionally stable, robust concrete elements

Perfect hold in the concrete bed

- Ideal coefficient of expansion, identical to that of the surrounding concrete

High drainage performance

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

Resistant to extreme temperatures and UV light

- Maximum resistance to frost and de-icing salt

- UV resistant

Fireproof

- Non-combustible construction material – Class A1

- No toxic smoke emission

Maximum durability

- Unsurpassed stability and durability

- Compressive strength far exceeding the requirements of EN 1433

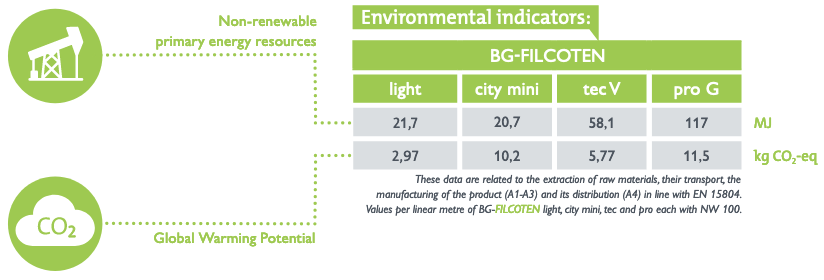

Sustainability advantage

Sustainability advantage

Verified life cycle assessment (LCA)

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

Resource efficiency

- 100% recyclable, certified

- Quality class U-A

Sustainable production

- Resource-efficient manufacturing process

- Up to 70% less sand and gravel

- Up to 55% less cement

- Up to 51% less water

Clean energy for clean products

- Manufactured using 100% green energy

- 17.56% from in-house photovoltaic plant

- No fossil fuels used whatsoever

Certified for sustainability and tested for hazardous substances

- Certified environmental and energy management to ISO 14001 or 50001 standards at the location in Oberwang, AT

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity; styrene-free

- Certified in acc. with KIWA BRL 5070

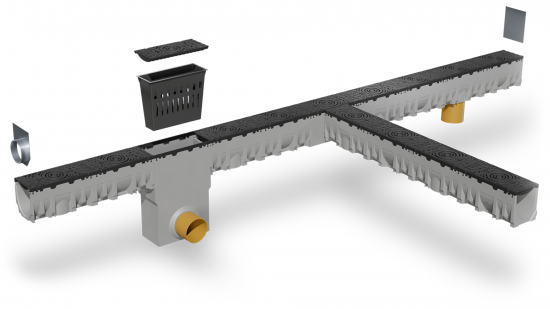

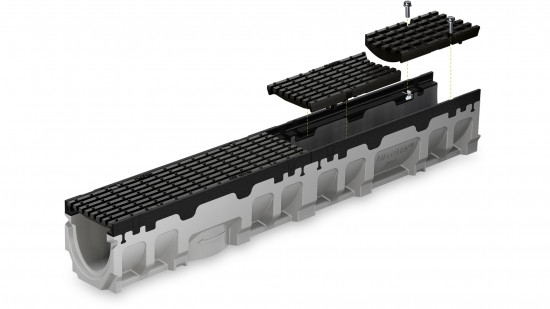

Only a heavyweight,

when it comes to features

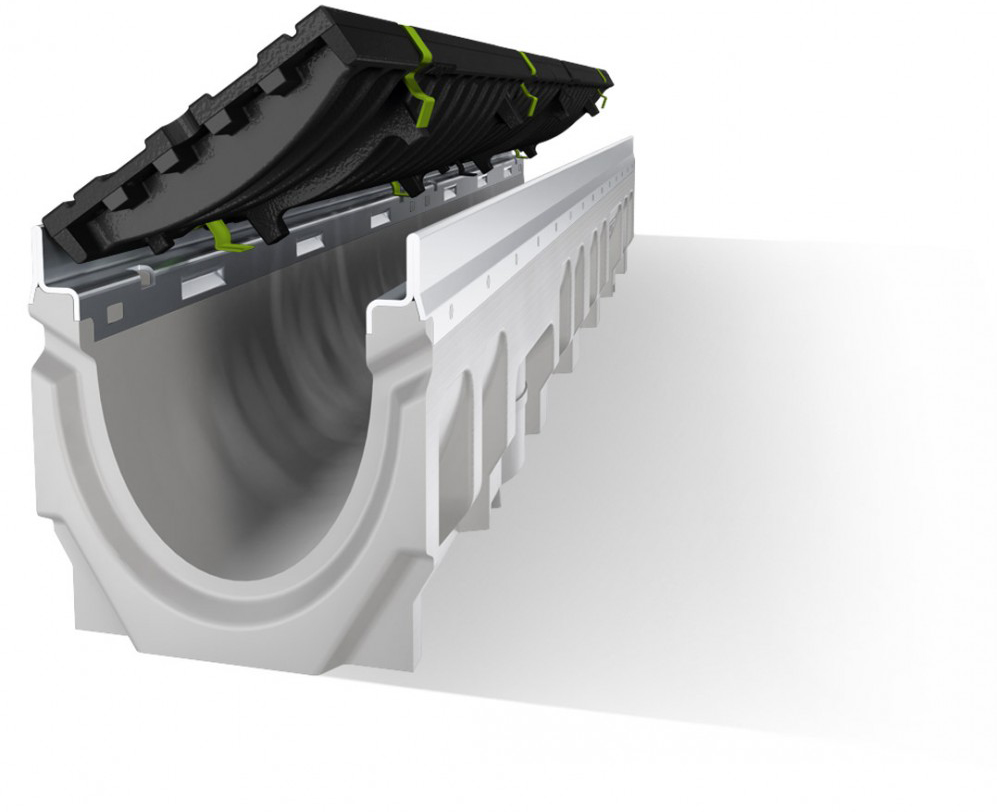

The advantages of BG-FILCOTEN® pro.

Only a heavyweight,

when it comes to features

The advantages of BG-FILCOTEN® pro.

Click on the green symbols in the image to find out more about the design of the BG-FILCOTEN® pro trench drain.

+

+

+

+

+

+

+

+

+

All product benefits

Any

questions?