Drainage of parking garages is faced with diverse challenges that are not easy to meet. FILCOTEN® parkline was developed especially for the complex requirements of parking garage construction and renovation.

BG-FILCOTEN parkline

Keep calm and park your car.

BG-FILCOTEN parkline

Keep calm and park your car.

<h5><strong>It’s complicated</strong></h5><p>There are diverse requirements for the drainage of parking garages. At first glance, meeting them seems to always require a compromise, with one of the problems remaining. On our quest for answers, we took a closer look at the needs of parking garage operators, and developed a well-thought-out solution.</p><h5> </h5><h5><strong>Hydraulic performance vs construction</strong></h5><p>Snow, rain or sludge – parking garages are faced with considerable amounts of water brought in by motor vehicles. This calls for a deeper channel with a greater hydraulic performance. On the other hand, deeper channels mean less reinforcement of the floor or roof construction and would severely weaken the structure’s cross-sections.</p><h5> </h5><h5><strong>Grate cover vs noise protection</strong></h5><p>Adding grates to flat drainage channels creates a smooth finish with the surrounding structure. However, in busy parking garages, this poses another problem: The channel will make a rattling sound whenever a vehicle drives over it at a speed common for parking garages – especially if it crosses the channel run in a lengthwise direction. Due to the concrete material, the disturbing noise is easily carried to adjacent parts of the building. This may cause noise pollution for residents, and even permanent complaints for parking garage operators. On the other hand, if the grate and the channel body are screwed tightly in place, this often leads to corrosion of the entire screwing.</p><p> </p><h5><strong>Material compatibility for durability</strong></h5><p>The longevity of a parking garage depends on the synergy of the materials used for construction. Adjoining materials should have similar properties in order to minimize tension and fissures. Especially in areas prone to dampness, even the smallest cracks can be a way in for harmful salts that attack the building structure. Traditional concrete is not suited for use in comb channels. Stainless steel channels provide a corrosion-free alternative, but they are very expensive.</p>

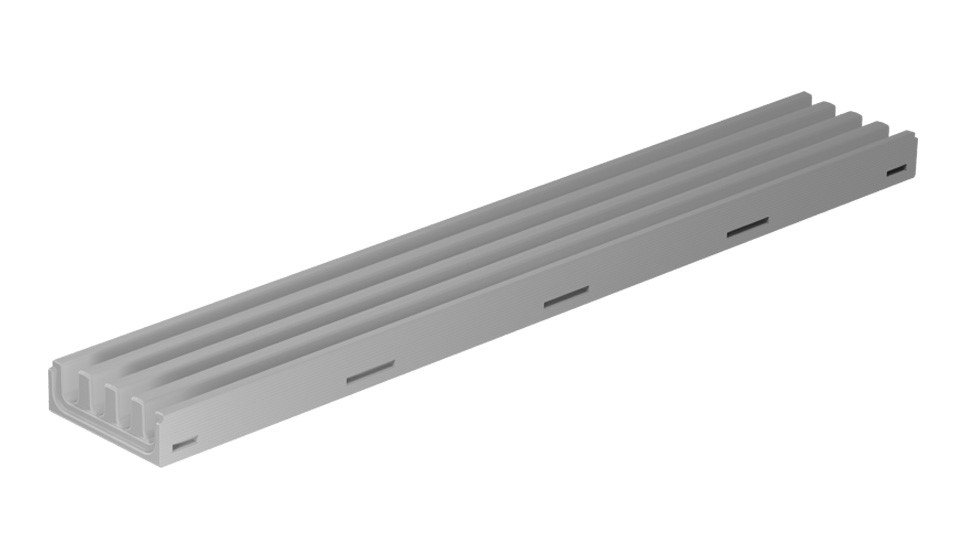

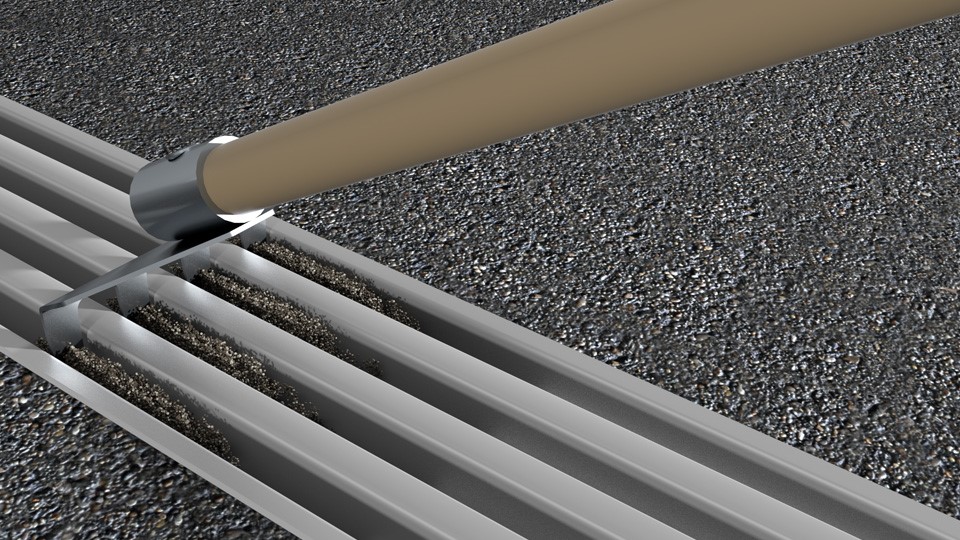

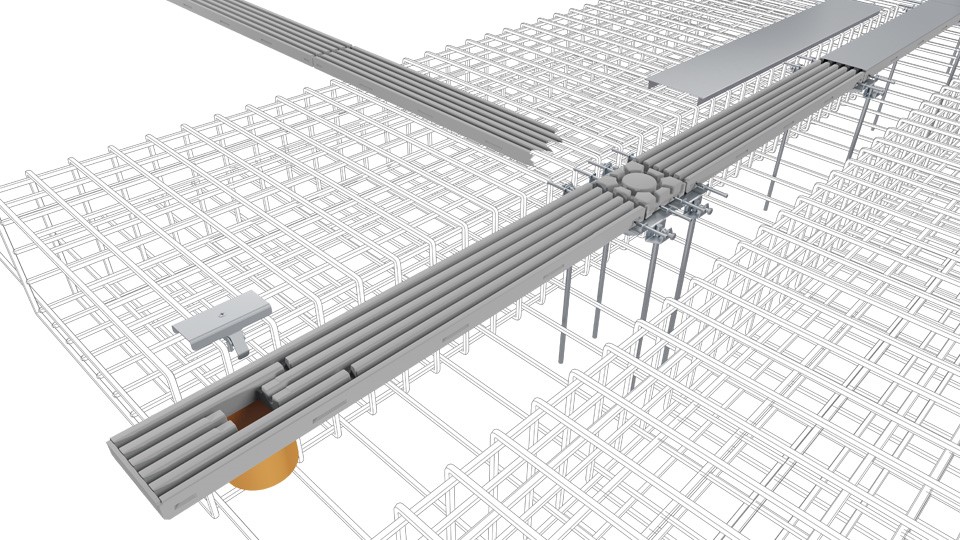

<h5><strong>BG-FILCOTEN parkline</strong></h5><p>BG-FILCOTEN® parkline is the first mass production-ready, cost-efficient comb channel made from high performance concrete (HPC) that meets the requirements of parking garage construction and renovation.</p><ul><li> </li><li>FILCOTEN® HPC has the same expansion coefficient as the surrounding concrete, which enables a permanently solid fit and minimizes tension.</li><li>Since the comb channel does not require a grate cover due to its monolithic structure, there is no rattling noise when vehicles drive over it. This significantly reduces noise pollution for adjacent buildings.</li><li>Thanks to its low height of only 35 or 50 mm, it practically has no impact on the static structure at all. At the same time, water is transported to the mid-channel outlet faster at the end of a run thanks to a channel body with interrupted ridges.</li><li> </li></ul><p>Also, the FILCOTEN® material is non-combustible – a crucial advantage when it comes to fire protection when used inside buildings.</p><p> </p>

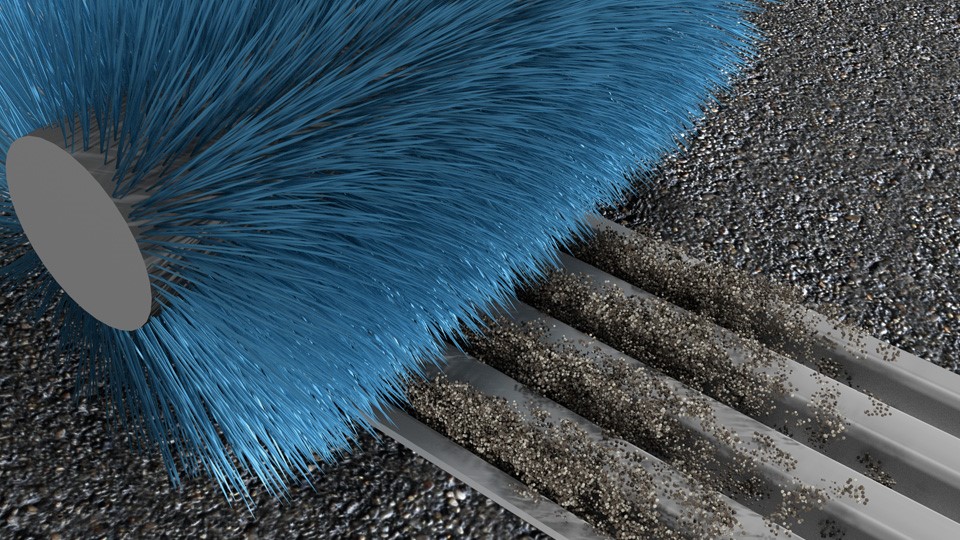

<h5><strong>A drainage channel perfect for green building</strong></h5><p>The FILCOTEN® HPC (high performance concrete) material also offers exceptionally sustainable properties. The cement-bound, mineral material is 100 % recyclable. Certified by the IBR, FILCOTEN® HPC is harmless to health and the environment, because it is organic and free from biocidal materials, solvents, VOCs or heavy metals. In addition, the production process is based entirely on an eco-friendly energy mix with an exceptional carbon footprint. Therefore, BG-FILCOTEN® parkline is perfectly suited for green building.</p><p> </p><h5><strong>Convenient accessories</strong></h5><p>Thanks to a number of well-though-out additions, planning, installation, use and maintenance of BG-FILCOTEN® parkline are especially efficient.</p><ul><li> </li><li>Installation supports with screw fixation simplify the installation of the channel: The channel body can be preinstalled braced on the casing, before being entirely cemented. This means heavy equipment is not required for the installation.</li><li>During the cementing process, a temporary construction cover protects the channel body.</li><li>An innovative connecting element enables junctions or T-/L-connectors.</li><li>The intelligent drainage cover made from V2A stainless steel is used as support and can simply be removed for cleaning.</li></ul><h5> </h5><h5><strong>Wide area of application</strong></h5><p>BG-FILCOTEN® parkline meets the complex requirements of parking garage planners and operators when it comes to the functionality and cost effectiveness of drainage systems. The material is also very sustainable. Furthermore, it is not limited for use in parking garages. BG-FILCOTEN® parkline is perfectly suited for both indoor and outdoor buildings that require low installation heights, excellent flow performance, high stability, noise protection and sustainable construction.</p><h5> </h5><h5><strong>Learn more about BG-FILCOTEN® parkline in</strong><a href="http://www.graspointner.at/fileadmin/Prospekte/Parkline_Broschuere_web.pdf" target="_blank"><strong> this brochure.</strong></a></h5>