Optimises every cable route

and your CO2 footprint.

Optimises every cable route

and your CO2 footprint.

Lived sustainability: FILCOTEN HPC (High Performance Concrete)

<ul> <li>Mineral high-performance concrete (dense, low-capillary, optimised microstructure)</li> <li>Extremely durable, stable and UV-resistant</li> <li>Extremely resistant to frost, de-icing salt, oil, petrol</li> <li>100% recyclable – quality class U-A (2)</li> <li>Certified environmental and energy management according to ISO</li> <li>14001 or 50001 at the Oberwang site, Austria</li> <li>IBR-certified (1), tested for: VOCs, styrene (3) and BTEX, heavy metals, radioactivity</li> </ul>1) Meets the strict criteria outlined by the Rosenheim Institute for Construction Biology (IBR). 2) Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)). 3) No use of synthetic resins.

+

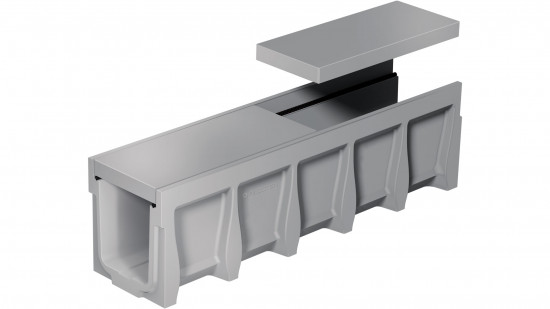

Maximum lateral stability

The solid ribs on the side walls ensure maximum stability.

+

Prevents shifting at the transition

With the tongue-and-groove system, the troughs are installed from top to bottom. This helps avoid any sideways shifting and prevents grit from entering the cavity.

+

The benefits at a glance:

<ul> <li>Lightweight yet stable component</li> <li>Environmentally friendly, 100% recyclable</li> <li>Quicker installation (manual installation possible) – less track obstruction time</li> <li>High dimensional accuracy and straightness with the tongue-and-groove system and trough installation from above</li> <li>The BG-RAIL FILCOTEN cable trough is lighter, narrower and more compact than conventional troughs. The easier and faster creation of mitre cuts saves time when diverting the run around pylons.</li> </ul>

The benefits at a glance

Trench belt

A trench belt can be deployed when needed and ensures a proper fit of the cover.

+

Smooth surface

The smooth internal surface of the BG-RAIL FILCOTEN cable trough makes it easier to pull in the cable strands.

+

Recess edge – outer edge of the trough

The upper edge serves as a guide to level the backfill material when creating paths.

+

Verified LCA (life cycle assessment)

<ul> <li>Reduced greenhouse gas emissions</li> <li>Manufactured with 100% green power</li> <li>Resource-efficient manufacturing process</li> </ul>

+

Cable trough cover

The cable trough cover protects cables from damage and harsh weather. All cable trough covers are produced with or without fibre reinforcement.

+

Anchoring pockets

The innovative FILCOTEN HPC production and moulding technology made it possible to design anchoring pockets for a concrete trough body to ensure an even better hold in the ballast bed.

+