Sustainability

at BG-Graspointner

Sustainability

at BG-Graspointner

Goodbye greenwashing, hello full transparency. How we prove sustainability instead of just claiming it.

How we prove sustainability instead of just claiming it.

material

sourcing

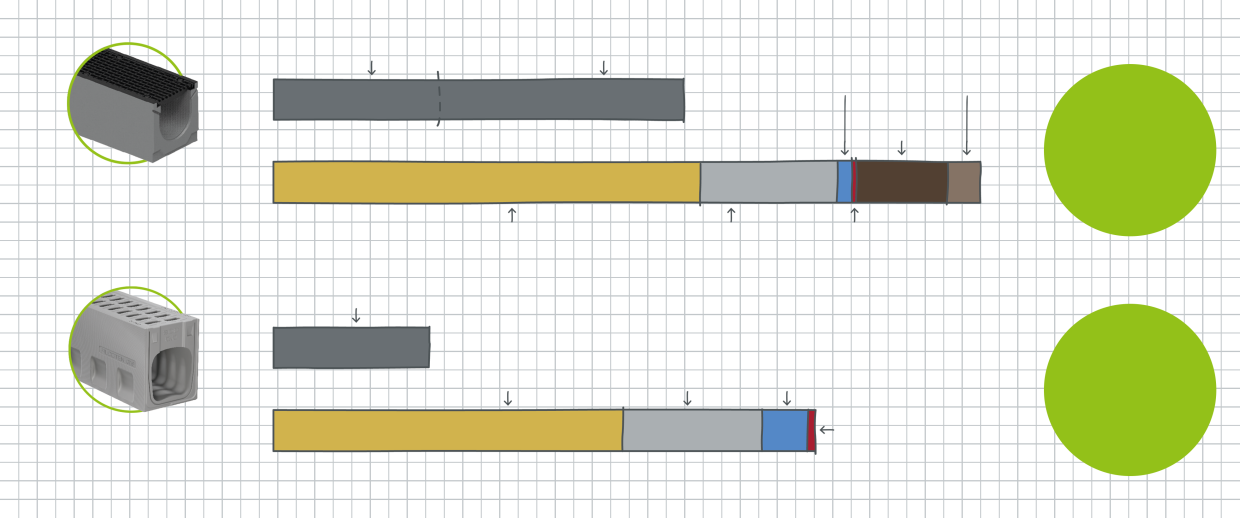

Extraction and purchase of resources or raw materials

GWP²⁾ = 69.77%

Delivery of resources and raw materials from the supplier to the manufacturer.

GWP²⁾ = 4.54%

Production of the product by the manufacturer

GWP²⁾ = 7.67%

Delivery of the product from the manufacturer to the customer.

GWP²⁾ = 18.02%

Total global warming potential savings of phases A1 – A4.

100% = 30.63 kg CO2-eq

Less raw material consumption ...

... less CO2 emission.

Less raw material consumption ...

... less CO2 emission.

Because sustainability and climate protection start with the material...

Because sustainability and climate protection start with the material...

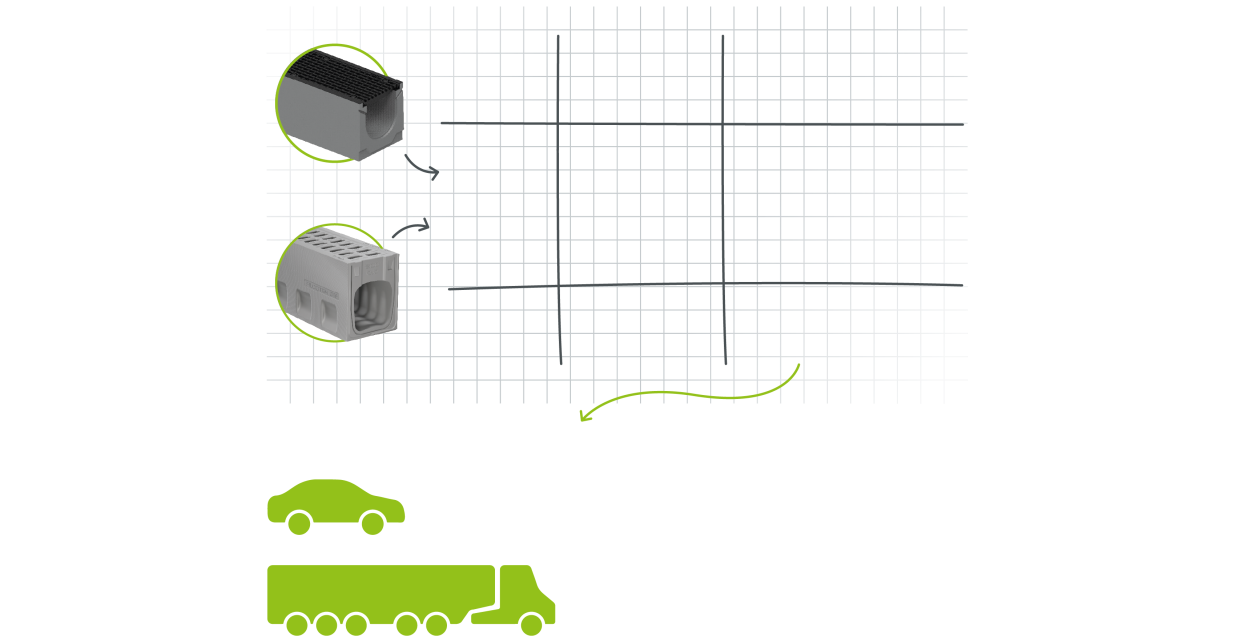

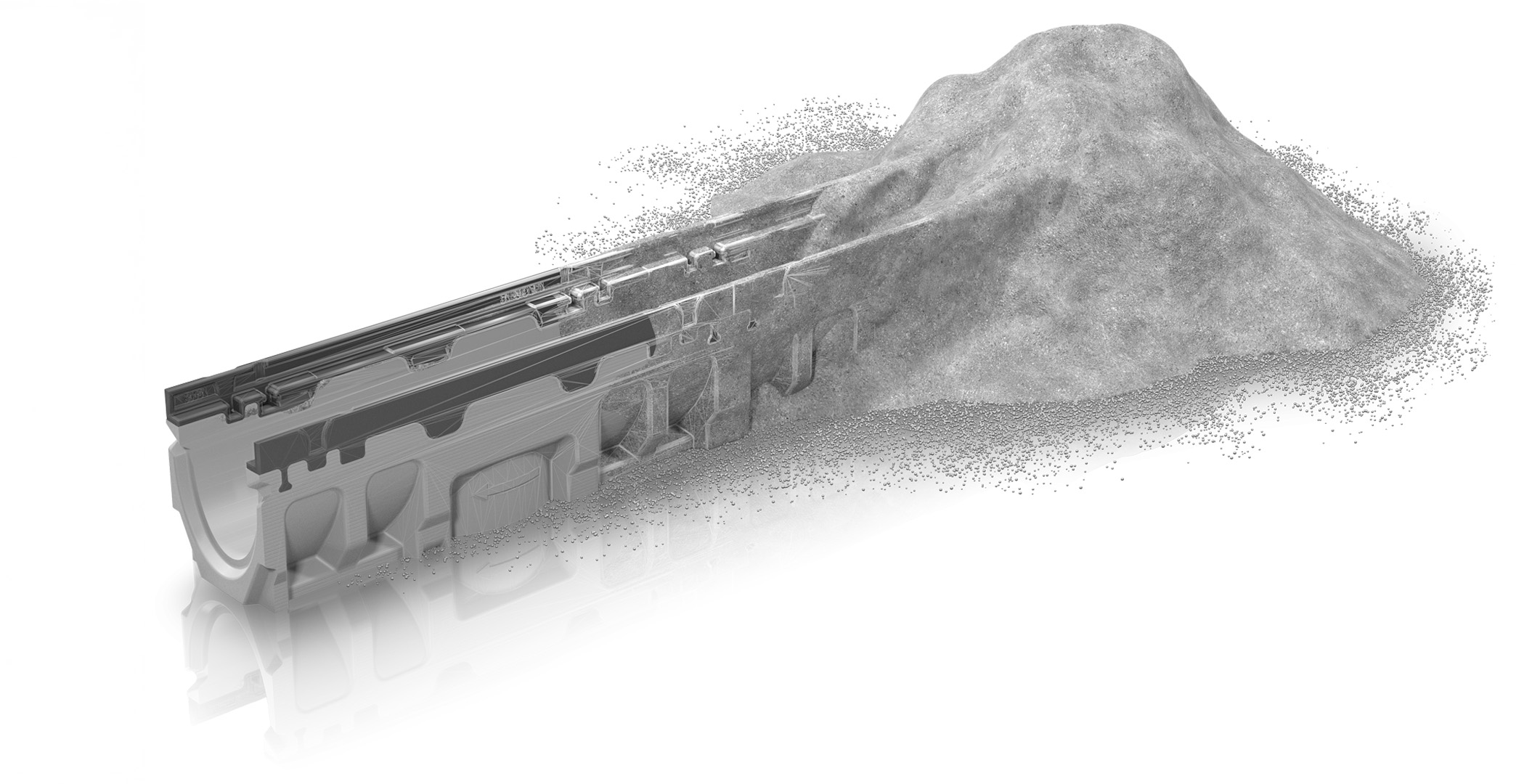

Simply effective and sustainable: The FILCOTEN® HPC formula ...

FILCOTEN® HPC

Like traditional concrete,

only better.

FILCOTEN® HPC

Like traditional concrete,

only better.

- 100% recyclable

- quality class U-A

- Verified ecological transparency

- in acc. with ISO 14025 and EN 15804:A2

- Ideal for sustainable construction projects

- manufactured using 100% green energy

- approx. 18% from in-house photovoltaic plant

- No fossil fuels used whatsoever

- Resource-efficient manufacturing process

- up to 70 % less sand and gravel

- up to 55% less cement

- up to 51% less water

- FILCOTEN® HPC enables lightweight construction

- quick and easy installation of dimensionally stable, robust concrete elements

- ideal coefficient of expansion, identical to that of the surrounding concrete

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

- Maximum resistance to frost and de-icing salt

- UV resistant

- Unsurpassed stability and durability

- Exceptional pressure resistance, well above the requirements in EN 1433

- Non-combustible building material – Class A1

- so no harmful smoke development

Any questions?

Want to find out more about us, request an offer or have a specific question on our products?

Then please get in touch. Send us a message using the contact form below. We look forward to hearing from you.