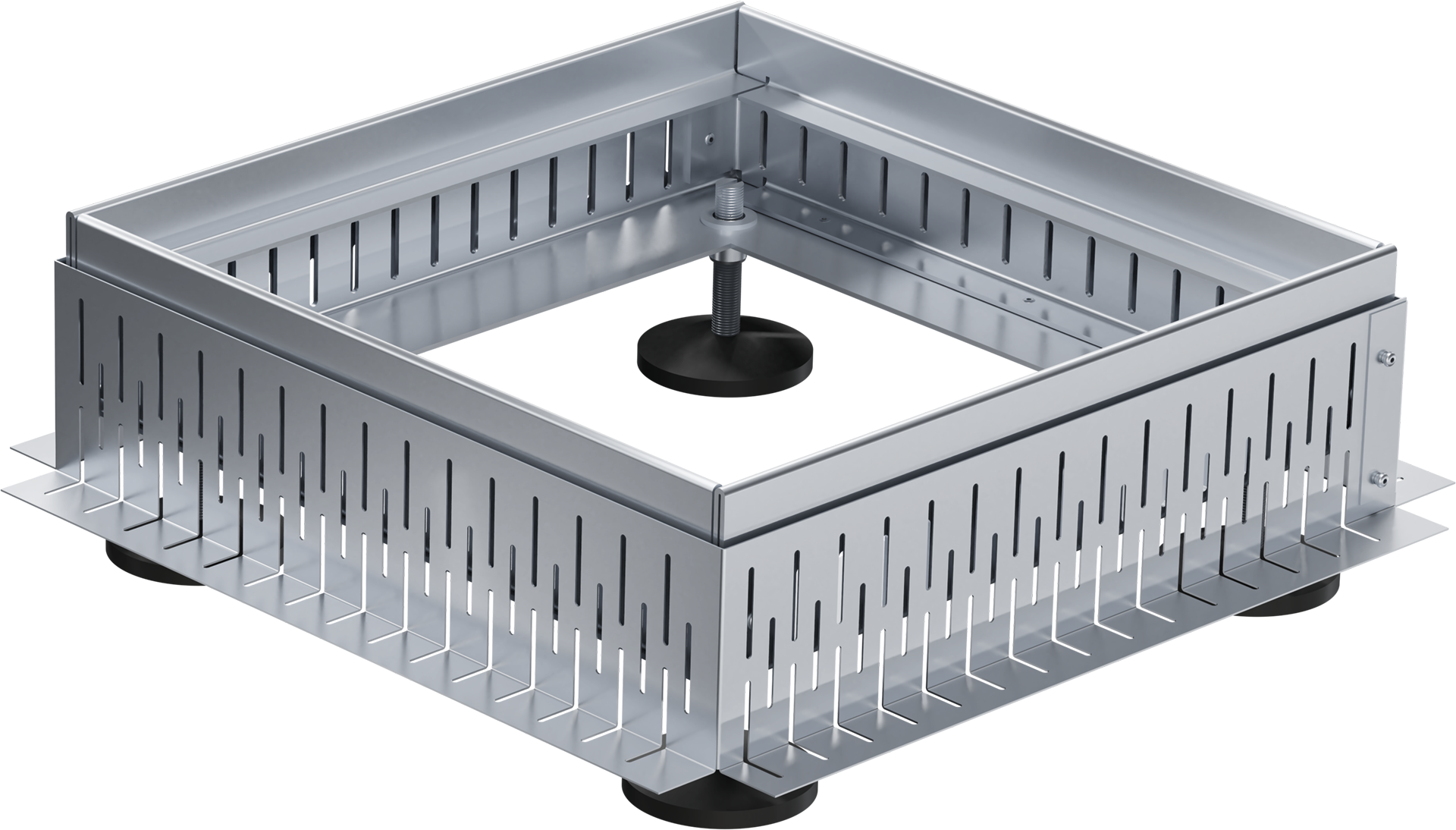

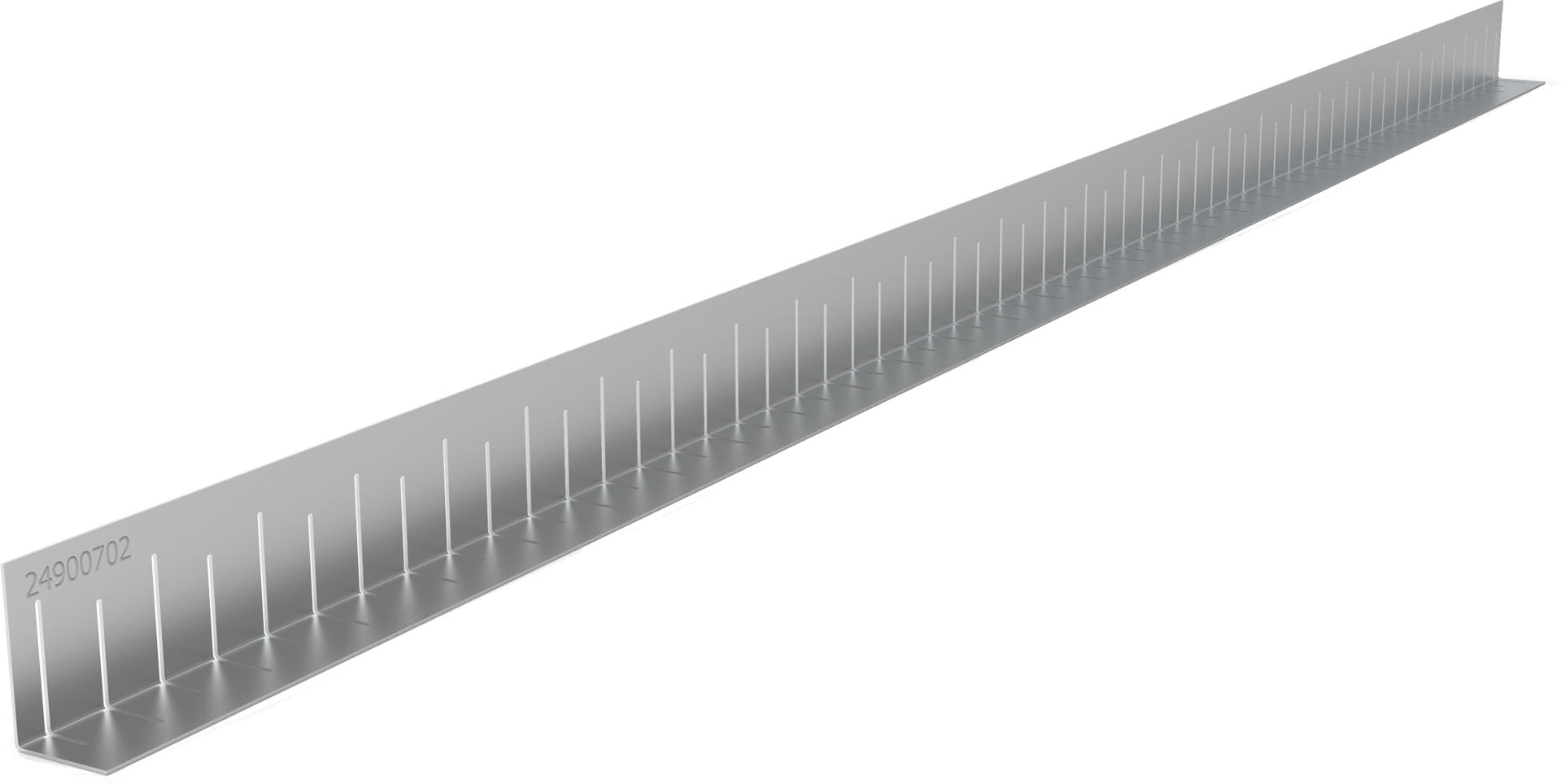

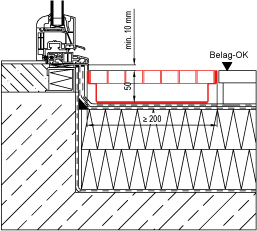

<h2>Connections of door and window elements in line with Austrian Standard B 3691:</h2><p> </p><figure class="table"><table><tbody><tr><td> </td><td>Min. width of the drainage channel</td><td>Min. height of the drainage channel in mm</td><td>Min. height above covering</td><td>Recommended product</td></tr><tr><td rowspan="2">Partially protected situation</td><td>120 mm (4.7″)</td><td>80</td><td>10</td><td>FA RB 130, fixed element height 80 FA RB 130, variable element height 80-120</td></tr><tr><td>200 mm (7.9″)</td><td>40</td><td>10</td><td>FA RB 200, fixed element height 50 BG-FA RB 200, variable element height 50-70</td></tr><tr><td rowspan="2">Unprotected situation</td><td>120 mm (4.7″)</td><td>180</td><td>10</td><td>FA RB 130, fixed element height 180</td></tr><tr><td>200 mm (7.9″)</td><td>90</td><td>10</td><td>FA RB 200, fixed element height 90 FA RB 200, variable element height 70-100</td></tr></tbody></table></figure>