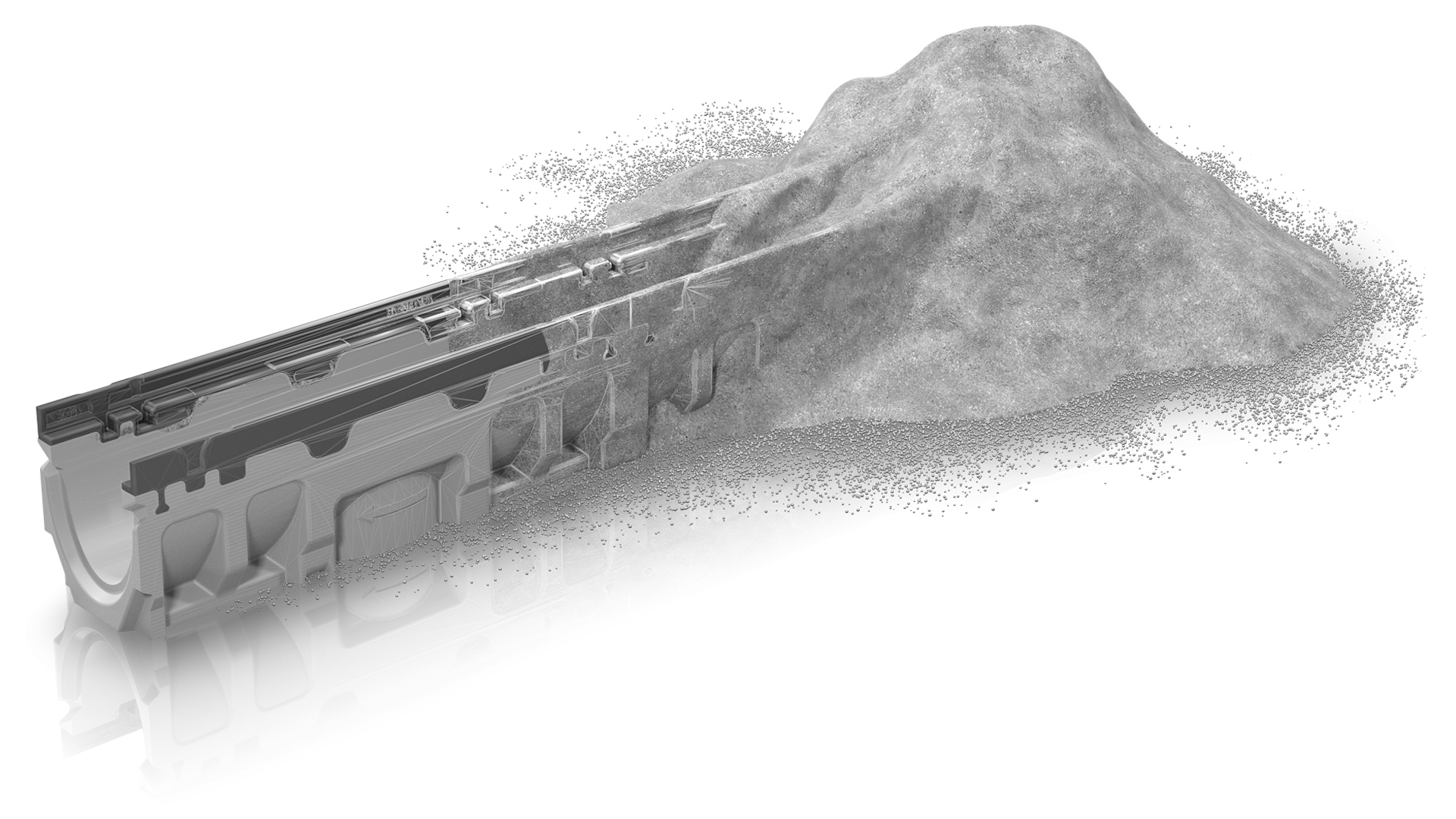

<p>Sustainability is one of the most important elements of our corporate culture. This can be seen from the materials, the manufacturing processes and the energy used. After all, we are a member of the<strong> Climate Alliance</strong> Austria, the country’s largest climate protection network, for a reason.</p><h2>Our view of entrepreneurship is not to look at the profit alone.</h2><p>The company’s success and development will always be closely connected to its responsibility to society – and for the environment. After all, what good is a huge profit if you can’t bare to look at yourself in the mirror at the end of the day?<br> </p><h2>Lived sustainability in all its facets.</h2><p>For this reason, the sustainable use of our environment is a key element of our corporate culture and more than just a marketing promise:<br> </p><h2>certified environmentally friendly production.</h2><p>When it comes to our production processes, we focus on the highest possible level of environmental protection, from the selection of raw materials through to avoiding excess waste. With this in mind, we have implemented a certified environmental and energy management system in accordance with ISO 14001 and 50001 at our location in Oberwang, Austria.<br> </p><h2>High-performance products: with a view to protecting people and nature.</h2><p>We develop our products with the aim of maximising their performance. And by performance, we also mean protecting people and the environment as much as possible.<br> </p><h2>Sustainable to the end: We use recyclable raw materials.</h2><p>Most of our products are made of mineral raw materials or metal. They are therefore 100% recyclable and can be assigned to quality class U-A according to the certification by the Salzburg Institute for Construction Engineering Research (bvfs), a state-accredited test and research facility for building construction and building materials.<br> </p><h2>Clean energy for clean products.</h2><p>We rely on the use of green energy. For our BG-FILCOTEN® products, we even use 100% renewable energies and no fossil fuels whatsoever.</p>